Today at Roughneck Chronicles

Yanmar Generator

Yanmar Generator

The special noise reduction patented cover, auto-return decompression, recoil starter, cooling systems that consist of 4-cycle, and air-cooled diesel engines are special features of the Yanmar generator. The Yanmar generator is set apart from other brand names such as Kubota, which makes much noise when it is operating. The Yanmar fuel tank holds 12.5 to 16 liters and gives maximum output of about 13 to 15 hours. Parts for the Yanmar Diesel Generator 5500 model are easily available in the market, which fact enhances its popularity worldwide....

Cost Of Hydrogen

Cost Of Hydrogen

The cost of hydrogen is definitely something which many people find interesting, especially as the hydrogen has become such a popular alternative of fuels such as diesel, propane and methane. Anyway, the truth is that determining what the hydrogenâs cost is quite more complicated than it seems. Why is that? You are probably thinking that itâs not true because there could not be anything complicated about saying what the cost of anything (even if it is fuel) is. However, it is obvious that you did not think about it twice...

Construction Management Degrees Online

Construction Management Degrees Online

As construction projects become increasingly complex, the need for highly trained and well-educated construction managers becomes more important as well. In order to make sure that there are individuals who meet the specific requirements for project managers, universities around the country are now starting to offer construction management degrees online. For years, the role of the construction manager has been filled with someone with a college degree in construction science or an engineering field, as well as on-the-job experience; if the construction manager did not have a degree, they had substantial...

Petroleum Technology Transfer Council

Petroleum Technology Transfer Council

The petroleum technology transfer council, is an organization that is established to provide for different services to the petroleum community, this council services are open for all and it the organization has decentralized office all over the nation, it should be noted that this council is a non profit organization, which was established by state institutions, oil producers and the department of Energy, its services are not only extended to mentioned organization but also extended to independent petroleum players in the industry. The petroleum technology transfer council has offices that...

Wind Electric Generators

Wind Electric Generators

Wind electric generators are some of the most helpful devices in the world of energy because they can generate a lot of electricity using only the power of the wind. The wind is something that occurs naturally anyway, so aside from building the actual machine to get the generated power, there is nothing more we need to do in order to maintain the wind electric generators. We can simply let them do their thing so to speak. This is good in this economy where so many people are getting paid...

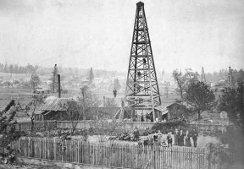

Roughneck Definition

![]() Exxonmobil

Exxonmobil

ExxonMobil is an American gas, and oil company. It became a company in late 1999 when two oil companies merged into one. Exxon and Mobil. The company descended from the former Standard Oil company founded by John D Rockefeller. The merger of Exxon and Mobil to...

Most Popular Articles

- Alberta Oil Field Jobs

- Contact Us

- Oil Rig Jobs

- Construction

- Entry Level Oil Rig Jobs

- Oil Rig Jobs

- Energy

- Oil Articles

- Generators

- Alaska Oil Field Jobs

- Mining

- Oil Rig Jobs Alberta

- Offshore Drilling Rig Jobs

- Entry Level Oil Rig Job

- Wind

- About Us

- Aluminum

- Cook

- Construction Bid Template

- Oil Platform Jobs